Search This Supplers Products:TowelHand TowelFace TowelBath TowelBeach TowelHotel Towel

-

For our company:

Company and factory integration

3 senior digital print colorists

9 years of home textile design experience

16 domestic and foreign monographs with professional digital printing knowledge

3 days proofing, 10 days delivery

A digital printing line that is the most advanced in the country and hopes to have more than 2 million 8 colors and 32 nozzles

A digital printing line of more than 600 million 8-color 64 nozzles imported by Zimmertime2018/07/20

PublisherMr.Busy

-

We can see that digital printing is a very high-quality technology, which makes the printing more convenient and faster. The traditional printing needs to be plated before printing, and the digital printing only needs to connect the files in the computer directly to the computer. can. Saving the cost of plate making also increases the speed of printing.

time2018/07/20

PublisherMr.Busy

-

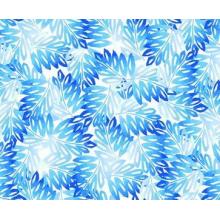

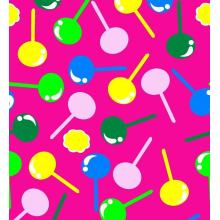

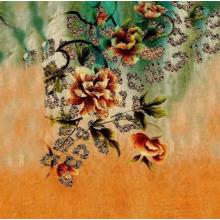

When we carry out the printing process, we must look at the overall quality of the product by the quality of the pattern printing. The good quality can effectively enhance the value of the processed product. Although there is a difference in processing fees, the products sold with good quality are also higher in price and more easily recognized by customers.

time2018/07/21

PublisherMr.Busy

-

1. Unsatisfactory color fastness to rubbing: In the process of using textiles, the degree of discoloration is different because different parts of the product are subjected to different degrees of friction.

2. The color fastness to washing is not acceptable: the products of high-grade fabrics are the most prone to such problems.

3. Insufficient color fastness to sun exposure: In the process of using the textile, the color will become lighter or fade when exposed to the sun.......time2018/07/21

PublisherMr.Busy

-

Jiangsu Busyman Textile Co., Ltd. was established in 2010 and is headquartered in Nantong, Jiangsu Province. It has 10 years of experience in towel production and OEM OEM processing. The company has a production area of 3,000 square meters, mainly produces and exports square towels, towels, sports towels, bath towels and other towel products and home textile products.

time2018/07/23

PublisherMr.Busy

-

1. The difference in craft

Cotton digital printing is usually set by the computer to print the pattern, the machine is finished.

Thermal transfer printing usually prints the pattern on a medium and then heats it on it when it is printed.

2. Which feels good?

The feel is definitely a good digital print, and the feeling of thermal transfer is a word "hard".time2018/07/23

PublisherMr.Busy

-

The coloring stage of digital printing is more conventional than manual experience. The color printing technology of digital printing is not only related to the accuracy of color, but also related to the quality of products and the speed of delivery.

time2018/07/24

PublisherMr.Busy

-

The four color standards are: C = cyan M = magenta Y = yellow K = black

Magenta + yellow = red; magenta + cyan = blue; cyan + yellow = green...time2018/07/24

PublisherMr.Busy

-

Compared with traditional printing, digital printing has been digitized in the process of printing, so that the design and production of printing products can not only quickly reflect the demand of their orders, but also the process of modification is very simple, and the products produced are also A greater degree of customer satisfaction.

time2018/07/25

PublisherMr.Busy

-

As both the customer and the manufacturer, it is desirable that the value of the color error of the product is preferably zero, but due to various limitations in production, it is impossible to completely eliminate the color error. The quality control can only be strengthened in each step, so that the color quality of the product is controlled within the minimum range and within the specified color difference.

time2018/07/25

PublisherMr.Busy

-

Moreover, digital printing, as an alternative to traditional printing, has been widely used in clothing, home textiles, industrial textiles, etc., and is suitable for various fibers and blends such as cotton, wool, silk, hemp, polyester, and nylon. Undoubtedly, the prospect of digital printing is very broad, and it has become a rare high-profit industry in the market, attracting many investors to enter the field.

time2018/07/26

PublisherMr.Busy

-

We can say that the current digital printing has entered a stage of breakthrough, and it will be more and more advanced, and digital printing needs to be developed. The industries such as nozzles, inks, and machinery need to be developed together. The nozzles are digitally printed. The position in the technology is quite important, and in the digital printing, the nozzle is also greatly affected.

time2018/07/26

PublisherMr.Busy

-

Nowadays, the environmental protection policy is becoming more and more strict. The traditional printing and dyeing industry has become the key controlled object of national energy conservation and emission reduction. Its environmental pollution has already restricted the sustainable development of the industry, and the traditional printing industry is also suffering. As a result, digital printing is actually an opportunity for sustained development.

time2018/07/27

PublisherMr.Busy

-

When doing digital printing, you must know the factory's production capacity correctly. Different digital printing factories have great differences in all aspects of production capacity. Therefore, when looking for a digital printing factory, you must find a processing factory that can be completed according to your own requirements, and complete it better in a better time.

time2018/07/27

PublisherMr.Busy

-

Nowadays, four colors, CMYK, are often used, so be sure to convert the image to CMYK mode when using a computer. Because the output is converted to a dot, that is, the precision pi, the theoretical precision of the printing image is 300dpi. Therefore, the pictures that people usually use cannot be displayed. It cannot be because the picture looks very beautiful on the computer.

time2018/07/28

PublisherMr.Busy

-

Digital printing has been in development for more than 20 years in China, and the range of digital printing in the market is also wider and wider, and the market share is gradually expanding. Nowadays, the environmental protection and re-examination,

time2018/07/28

PublisherMr.Busy

-

Although it is in the midsummer, the cotton printing products on the Chinese market are selling well in the old days. Nowadays, various kinds of pure cotton direct-injection printing products are emerging one after another. The sales show a clear differentiation pattern. Some large factories continue to climb with their own strength and high-quality product sales, but some small and medium-sized business households still need to improve their transactions.

time2018/07/30

PublisherMr.Busy

-

The washing fastness can be up to 4 grades, the wind and the sun are fading, and the hand washing machine does not fade. In terms of color fastness and other aspects will have a very good performance.

time2018/07/30

PublisherMr.Busy

-

Alkali resistance

High temperature stability

Low temperature stability

Electrolyte stability

Shear stability

Anion activity compatibilitytime2018/07/31

PublisherMr.Busy

-

-

We all know that the quality of products in the enterprise is the lifeline of enterprise development, and it is also the core competitiveness of competition between us and our peers. As for the increasingly demanding requirements of modern consumers, their pursuit of product quality has become higher and higher, and they are particularly concerned about after-sales service, so we should do more to strengthen product quality and improve after-sales service quality. .

time2018/08/01

PublisherMr.Busy

-

In the process of printing, it is necessary to clean the pipelines in the equipment in time, and the internal filter is cleaned to keep the contacts from being blocked. In the process of using, it can be in a relatively normal state. This will not waste too much ink when used.

time2018/08/01

PublisherMr.Busy

-

1、数码印花标准品与样品的大小是否一致

2、温度和湿度的控制是否一致

3、织物样式和结构是否一致

4、颜色和恒定性是否一致

5、视角、观察者和照明条件等色现象是否一致

6、计算机测色配色是否正常。time2018/08/02

PublisherMr.Busy

-

Digital printing nozzles are an important accessory throughout the printing process. What is the requirement for the digital printing on the nozzle?

The first is that the durability and life of the nozzle should be long enough, because the price of the nozzle is relatively high, so the cost will be relatively high. If the life of the nozzle is long, a lot of cost can be saved.time2018/08/02

PublisherMr.Busy

-

Nowadays, due to the serious pollution of traditional printing, high proofing cost and long consumption cycle, digital printing technology with low energy consumption, adapting to small batch production and green energy saving has emerged, but it is also used in digital printing. There will be some defects in the finished product.

time2018/08/03

PublisherMr.Busy

-

In the digital printing process, many digital printing companies will have more or less ink waste in the printing process. As a printing product with low price in digital printing, it can save some ink in printing. It saves costs.

time2018/08/03

PublisherMr.Busy

-

In the digital printing, there is a kind of thing that is often used, and it is called "thermal transfer paper" in the printing industry. Thermal transfer paper is a special type of paper used in digital thermal transfer printing, which functions as a transfer pattern in the process. There are currently four common process usages for digital thermal transfer printing.

time2018/08/04

PublisherMr.Busy

-

The selfish boss does not do much, and the boss who treats his employee as a family will get the same effort from the family.

time2018/08/04

PublisherMr.Busy

-

In recent years, the state has strictly investigated pollution. Traditional printing has caused a lot of good and pollution in the production process, so traditional printing has a lot of influence in the current market. Moreover, with the development of society, people's quality of life is constantly improving, so traditional printing can not meet the current market demand.

time2018/08/05

PublisherMr.Busy

-

The screen display method is to adjust the color of the image by adjusting the color displayed on the screen. The color menu is usually used to select or adjust the color on the screen. This method is one of the more common methods used by designers.

time2018/08/05

PublisherMr.Busy

-

The current digital printing is indeed a big advantage in the printing industry, and the market share is also getting higher and higher. Just because of the current variety of printed fabrics, there are various kinds of cotton, polyester, and chemical fiber. But for now, there are some problems with cotton fabrics.

time2018/08/06

PublisherMr.Busy

-

In traditional printed products, the color paste content may contain 30%-50% dye, and the rest are basically thinner and dispersant. The purity of the ink dyes required for digital printing is very high, and the state of the particles. The color development of dye chromophores must be very strong. The concentration of the commercial printing dye is about 10%.

time2018/08/06

PublisherMr.Busy

-

traditional printing, because of the plate making, for the sake of the sample, it only takes about two weeks to make a sample. It is simply impossible to meet the requirements of customers for fast samples. The digital printing can be delivered in a few days without the need for plate making, meeting the requirements of the current fast samples.

time2018/08/07

PublisherMr.Busy

-

In the current digital printing, equipment, nozzles and inks can be said to be the most important accessories for digital printing. In digital printing consumables, ink is the main factor affecting the quality of printing. If you use unsuitable ink, it will not only seriously affect The quality of the print, but also damage to the digital printing machine, and the quality of the ink will determine the life of the nozzle. It can be called the blood of the whole system.

time2018/08/07

PublisherMr.Busy