Search This Supplers Products:TowelHand TowelFace TowelBath TowelBeach TowelHotel Towel

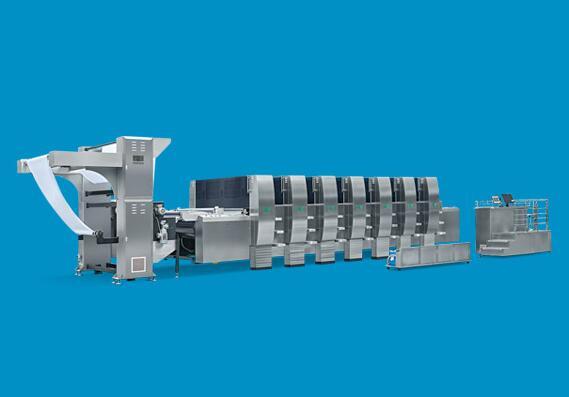

Digital Printing Direct Injection Machine Maintenance

publisherMr.Busy

time2018/06/08

- When the digital printing machine is in normal operation, the front cover must be covered to prevent dust or other hard objects from entering the interior of the machine, thus hindering the operation of the printer carriage. It is forbidden to turn off the power when the digital printer is powered on. This will damage the inkjet port of the inkjet printer and the parallel port of the PC. In severe cases, the motherboard of the PC may be damaged.

The market share of digital printing is increasing day by day. Compared with traditional printing, the advantages of digital printing are too many. Therefore, more and more companies are thinking of taking digital printing equipment to seize the market.

Everyone knows that digital printing machines are expensive, and it is indeed a large expenditure as a company's cost. Therefore, the maintenance of digital printing machines is essential.

Here's to introduce some digital printing machine maintenance methods

1. Do not touch the grating strip of the direct-stamping digital printing machine with your hands. It should be maintained in daily life. Do not allow it to be contaminated with dust to prevent inaccurate positioning and cause printing errors.

2, shut down

When the power is turned off, the nozzle is returned to the initial position. This not only can reduce the waste of ink and reduce the production cost, but also the nozzle can be sealed by the protection cover in the initial position, and the nozzle can be protected from clogging.

3, digital printing machine environment clean

If there is too much dust and other particulate matter in the factory, it is very easy to cause insufficient lubrication of the guide shaft of the trolley, which may cause the digital printing machine nozzle to not move smoothly during the printing process. This will eventually result in reduced printing accuracy or wear of the impacting mechanical frame. Deadlock may occur.

4, long-term unused ink cartridges should be placed at room temperature

If the ink evaporates easily under high temperature or exposure, it will cause the ink to settle and solidify later, which will eventually cause the nozzle to clog. In addition, under the environment of low temperature and humidity, the circuit and ink of the direct-injection digital printing machine nozzle are particularly prone to problems.

6, to ensure the stability of the direct-injection digital printing machine work platform, do not place the top of the goods.

When the digital printing machine is in normal operation, the front cover must be covered to prevent dust or other hard objects from entering the interior of the machine, thus hindering the operation of the printer carriage. It is forbidden to turn off the power when the digital printer is powered on. This will damage the inkjet port of the inkjet printer and the parallel port of the PC. In severe cases, the motherboard of the PC may be damaged.

The above is Digital Printing Direct Injection Machine Maintenance.editor introduced to everyone .If you want to know more about digital printing towel related content , please pay attention to Jiangsu Busyman Textile Co., Ltd.http://..........com/